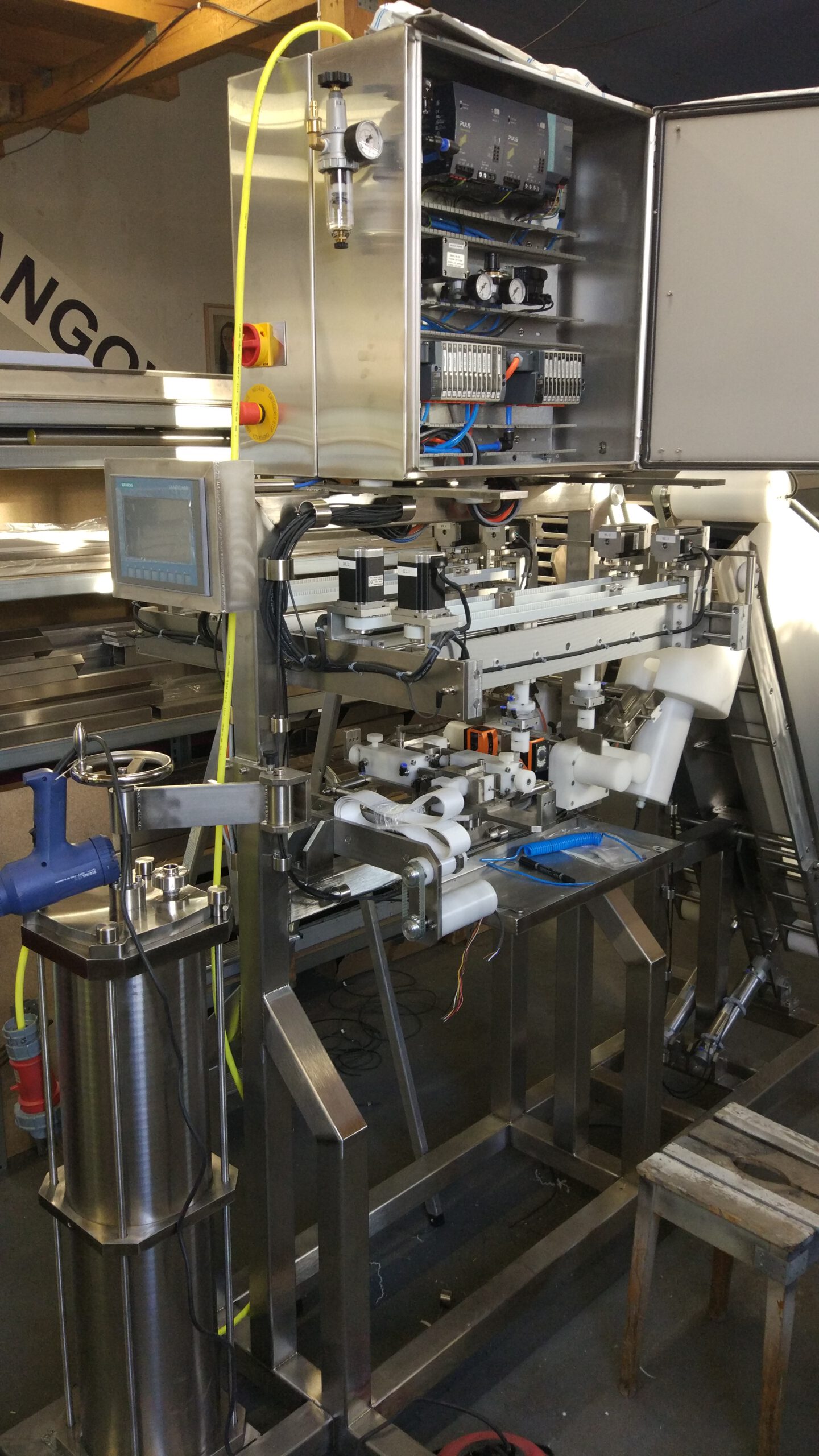

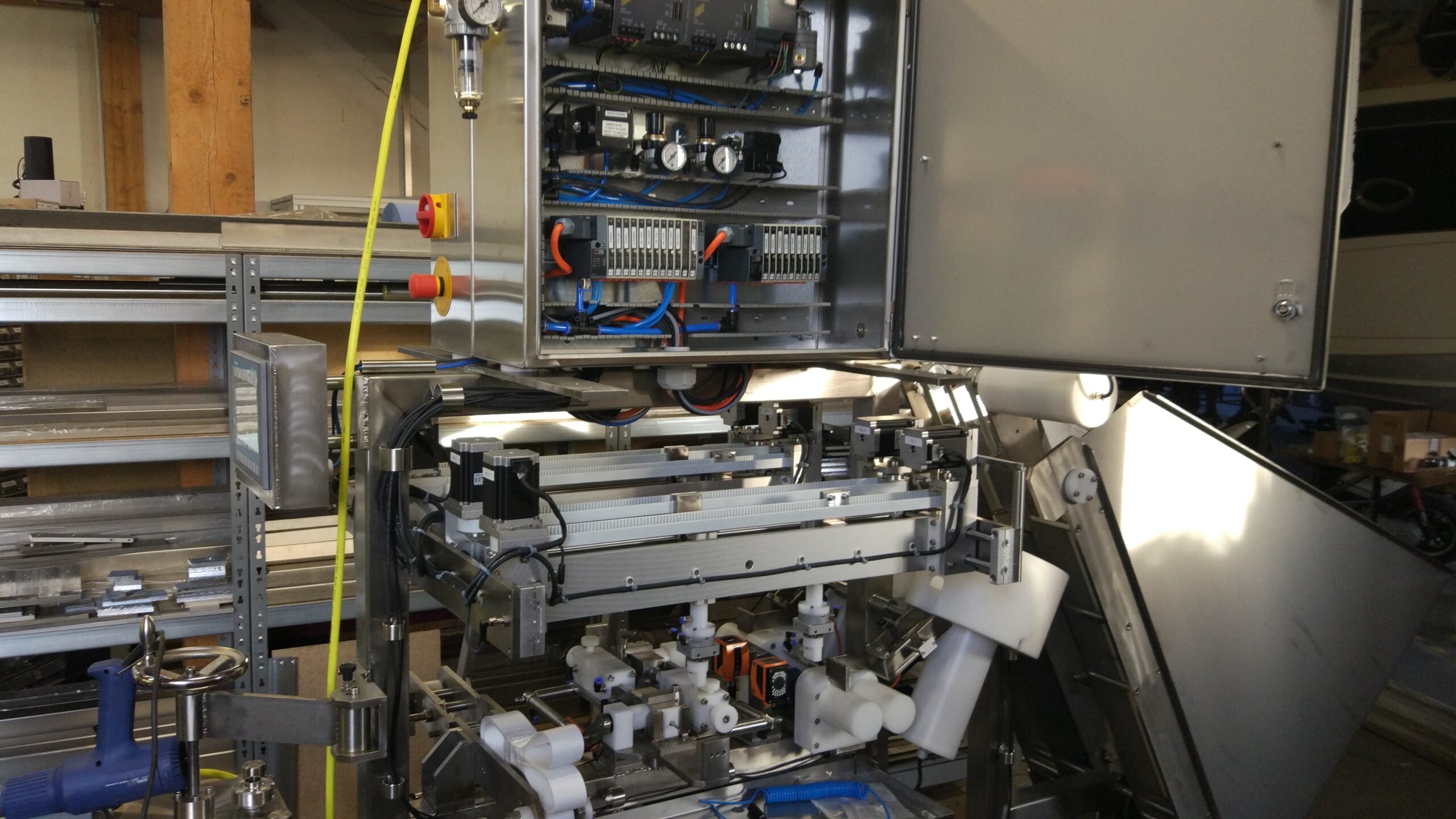

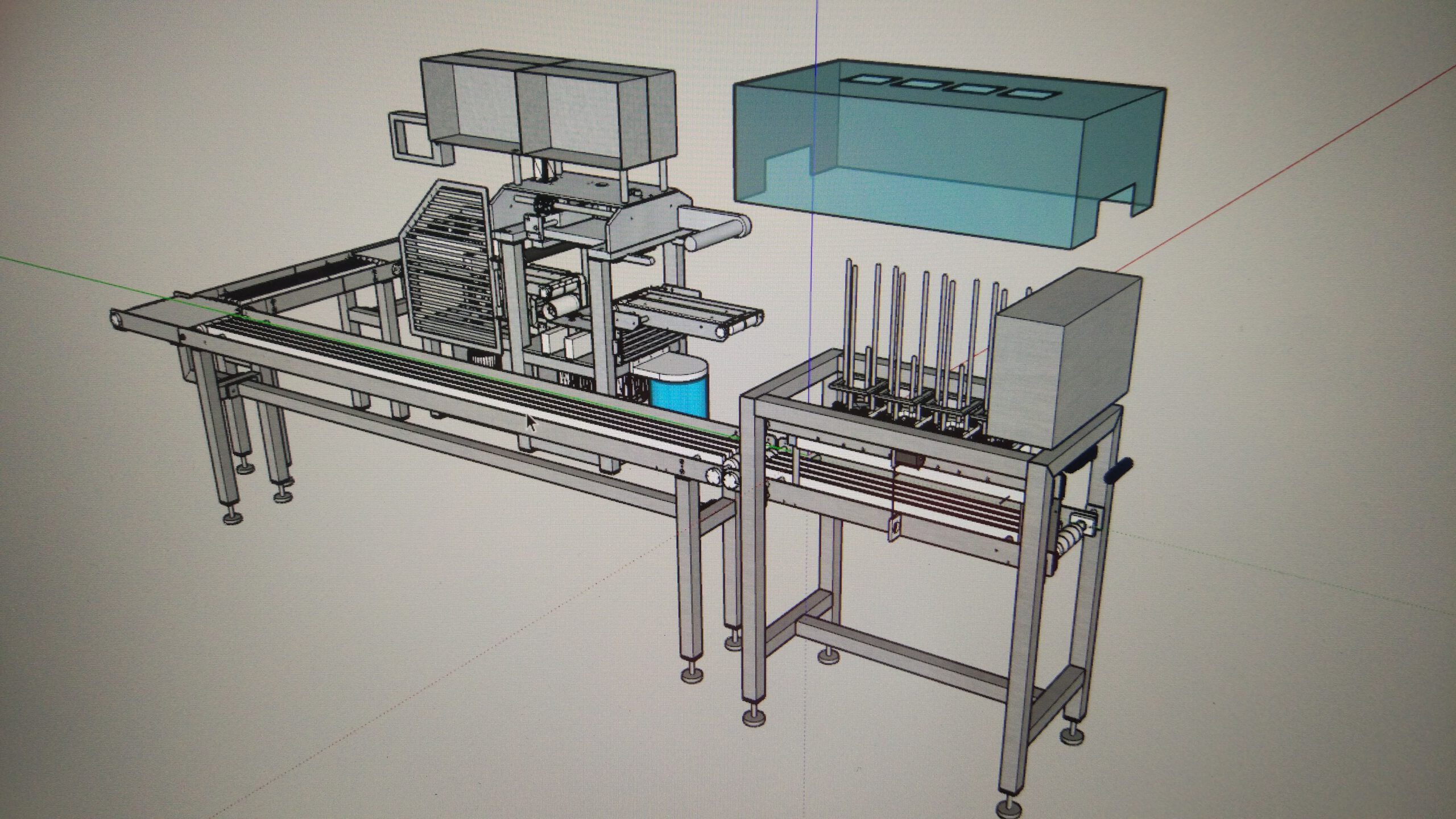

Specialized Destacking Unit: Complete In-House Design and Production

We completed a comprehensive project involving the design, fabrication, and assembly of a custom destacking unit for an industrial production line. This specialized machine was entirely developed in-house, showcasing our ability to deliver complex and highly tailored solutions that meet the specific needs of our clients. Our in-house manufacturing capabilities allowed us to maintain strict quality control over every aspect of the machine’s build, from initial design to final assembly.